- Top Results

- Community

- Nexeed Automation

- Technology packs and Assist functions

- Re: Integrated robotics - slow moving through joint blended points

We are still working on migrating to the new Bosch Connected Industry Online Portal. Stay tuned! Click here for the latest updates.

Integrated robotics - slow moving through joint blended points

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Integrated robotics - slow moving through joint blended points

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

05-25-2022 11:34 AM

The robot slows down significantly when passing help points. All my help points are set as blended joints, blending 50 mm post blending 50 mm (see screen). I tried changing the settings to PTP blended, but the result was the same. I discuss this with Stäubli. I sent them video trajectories, record and screenshots of setings of the points. It got through to the uniVal developers and they wondered if the correct function blocks,MC_MoveAxisAbsolute, Direct and Linear were being used and on follow up if they were waiting for the MC_GroupContinue statuses which should be the correct function block to use.

Thank you in advance for reply.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-06-2022 08:10 AM

Just for your information - we are currently in contact with stäubli because of your problem...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-06-2022 01:42 PM

Can you send the program and the robot folder from the target system to our helpdesk (Nexeed.helpdesk(at)bosch.com ),

so that we can investigate it ?

And one more thing :

In the Logfile you move "linear blended" from the "help-points" to the "nest-offset-points" and vice versa .

If there are no collisions possible, then I would recommend that these movements also be executed as "joints blended"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-13-2022 04:10 PM

Thank you for the warning, I have modified the movement from the help point to the offset point to PTP_BLENDED, since the AddOffsetRobotPointToList method removes the joint coordinates. Based on this, I tried changing all the help points to PTP_BLENDED, but the behavior here remained the same.

What exactly folder do you mean? And which program (PLC project, ...)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-18-2022 11:23 AM

Yes, please send us the complete PLC and CpStudio project with your STD folder.

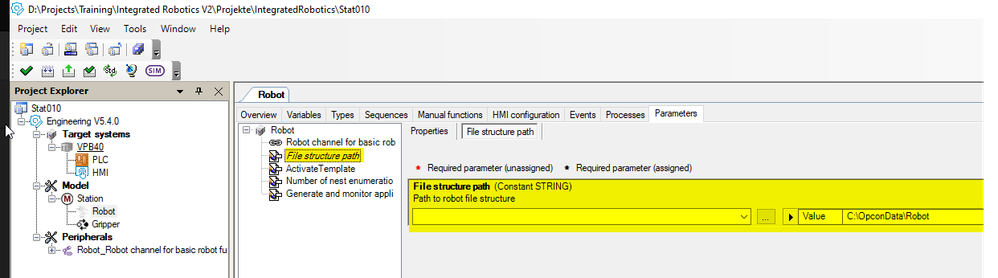

And the Robot folder from the target system, which you have configured in the ProgrammableRobotObject parameters

- « Previous

- Next »

Still looking for something?

- Top Results