- Top Results

- Community

- Nexeed Automation

- Control plus

- Re: KUKA ROBOT SYSTEM ERROR: 'Dynamic brake active' error code 108

We are still working on migrating to the new Bosch Connected Industry Online Portal. Stay tuned! Click here for the latest updates.

KUKA ROBOT SYSTEM ERROR: 'Dynamic brake active' error code 108

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

10-03-2022 04:57 PM

Hello,

I have met a problem with kuka Krc4 robot. When the robot running in automode, it will stop randomly with 'Dynamic brake active' message(Error code 108). After robot stopped, this error message will disappear but recorded in error history log. I need to switch plc's mode so that the error can be cleared. Doesn't any one knows why this error happened and how to solve it?

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

10-04-2022 03:06 PM - edited 10-04-2022 03:11 PM

Have you spoken to Kuka support ?

To me it sounds like a problem with the Kuka robot - the PLC just shows this error and is not the cause of the error...

I could imagine that the robot is perhaps overloaded and then makes an emergency braking,

because the axis controller can no longer hold the axis in position...

Or do you use the safe-operation package?

Maybe a safe speed / position is violated and that is the reason for the braking ?

Have you looked at the Kuka panel to see if an error message was logged there ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

10-12-2022 01:26 PM

Hello Thorsten:

Thank you for replying. I checked robot and there is no safe-operation package in it.

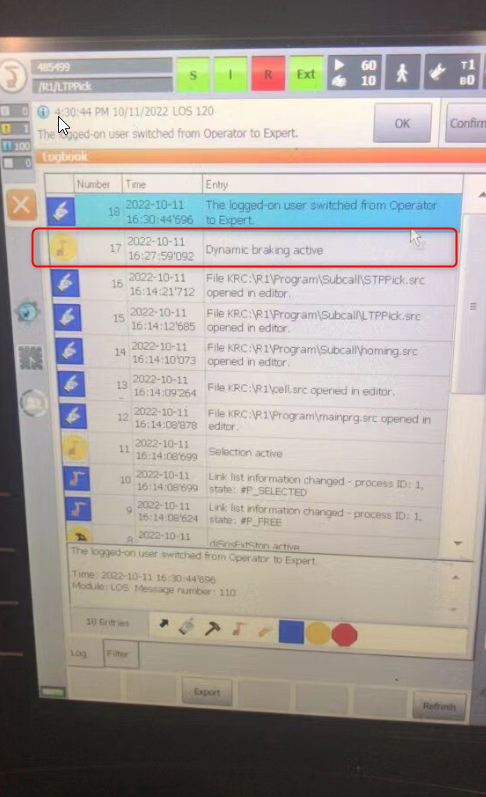

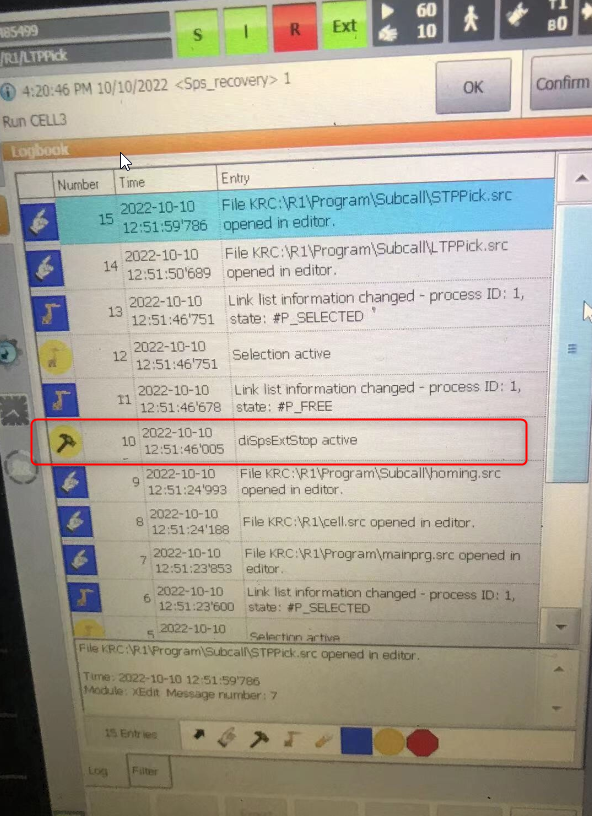

There are two different error messages in kuka history log. Both of them will cause robot stopped. You can find from the following pictures.

I also contact kuka support. They told me the first error 'Dynamic brake active' is just general warning and can't represent anything. But the second one, they said plc set diSpsExt_Stop signal during normal running. This is wrong handshake sequence at that time. But I confirmed with customer that no one switch the mode or pressed hold button during automode. It's quite strange. Did you also faced this situation before when testing KUKA robot object?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-03-2022 11:50 AM - edited 11-03-2022 12:31 PM

Such a problem has not been reported back to us yet.

However, the time stamps of these 2 error messages (screenshots) are also far apart, so that they are probably not directly related...

The PLC stop signal is always set when an operating mode change or a cancel is executed. It is also set when you press the Hold button in the HMI...

I don't think it is a general handshake problem, because then the robot would have to stop all the time and not only sporadically...

how often does this happen ?

Another question :

this message 108 comes to the PLC via the Robot.Unit.OutImm.AplErrNo ?

Do you enter this message as an event yourself, or have you activated the automatic entry of the application error in the NexeedRobot object ?

If you have activated the automatic entry, try entering the messages only as a warning, then the unit remains ready and can continue to execute commands - then you should be able to determine directly whether the robot stops because the unit switches to error or whether the robot stops because of the message from Kuka ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-07-2022 09:31 AM

I also don't think it is handshake problem. This error is not from Robot.Unit.OutImm.AplErrNo. It's an error from _robotState.StopMess and showing as 'Robot fault : robot has collective fault'. It's happening not quite offen. Properly one time in an hour.

When it happens, robot program will stop always at the same line. And we need to switch to home mode and call robot's home order to recover it. And then robot can start running.

Currently I made a recover function in automode. When plc detects this situation, it will clear error automatically so robot's ExecState can be ready. And then call robot's home order to recover it. Lastly plc go back to call robot's last command again.

It's quite diffcult to find the root case from plc side. Or you have any other suggestions?

Still looking for something?

- Top Results