- Top Results

We are still working on migrating to the new Bosch Connected Industry Online Portal. Stay tuned! Click here for the latest updates.

24 tips (Advent calendar) for Control plus programmers

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

24 tips (Advent calendar) for Control plus programmers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-06-2021 09:18 AM - edited 01-13-2022 01:03 PM

Hey, it’s december. The time when the day starts with opening a door of an Advent calendar.

Check out the official BCI Advent calendar on LinkedIn with some interesting piece of information every day.

But just these days I noticed in a discussion that there are so many small improvements from Control plus bundle V1.0 to V2.3 that some of you maybe missed. What would be more obvious than showing you a tip every day ...

#01 #02 #03 #04 #05 #06

#07 #08 #09 #10 #11 #12

#13 #14 #15 #16 #17 #18

#19 #20 #21 #22 #23 #24

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-10-2021 10:09 AM

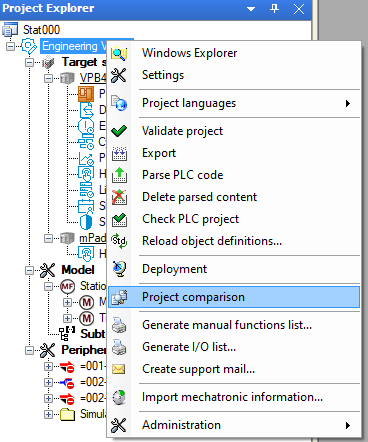

Do you know that Control plus Studio has a project compare function?

As most of the work in Control plus Studio is exported to files it is also possible to compare the station folder, for example with Beyond Compare.

Additionally the PLC editors have a quite powerful compare function. TwinCAT has the Project Compare tool in the Windows start menu, in ctrlX it is included in the PLC editor under Project > Compare.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-11-2021 07:40 AM

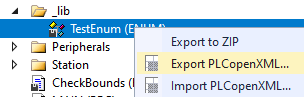

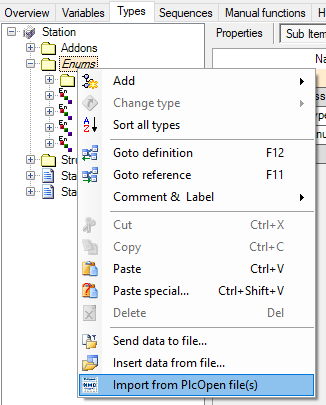

You can import PlcOpenXml in Control plus Studio. This helps if you want to move structures, enums or FB definitions from the PLC editor into Control plus Studio.

Export PlcOpenXml in the PLC editor:

Then import PlcOpenXml in Control plus Studio:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-12-2021

10:55 AM

- last edited on

12-13-2021

08:14 AM

by

nexidator

![]()

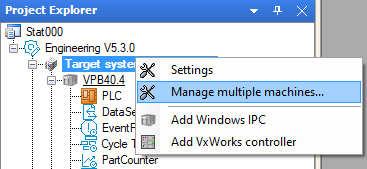

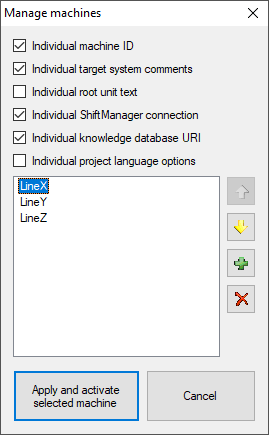

If you have two or more machines that are (almost) identical you can manage them in one Control plus Studio project. The target system settings can be managed in this menu:

There are several options to manage two identical machines in one production line or two identical machines in different production lines, for example:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-13-2021 02:31 PM

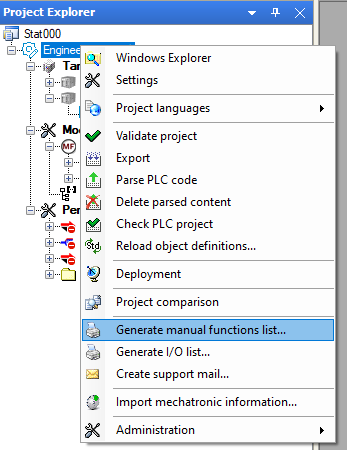

During commissioning all manual functions need to be tested. There are two possibilities to get an overview of what has been tested:

- Generate a list of manual functions like you can do for the digital IO. Mark all manual functions that you have tested in the printed list.

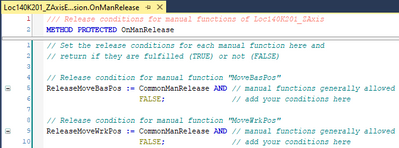

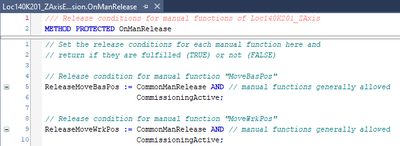

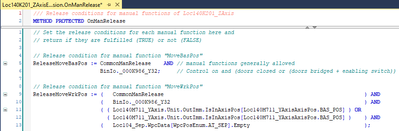

- A smarter solution uses the manual function conditions in the methods OnManRelease:

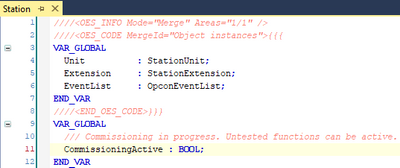

Create a global variable called CommissingActive:

Use Search & Replace in the PLC editor (CTRL+H):

Find what:

FALSE; // add your conditions here

Replace with:

CommissioningActive;

Now you can release all manual functions by setting the commissioning variable TRUE (but be careful!):

When testing a manual function replace the commissing variable with the real condition. At the end of the commissing the variable should not be used anymore and can be removed again.

Additional tip:

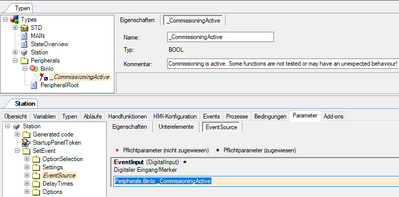

Create a commissioning BinIo flag in Control plus Studio and use a Set Event Addon to automatically show a warning if the commissioning flag is set:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-14-2021 11:50 AM

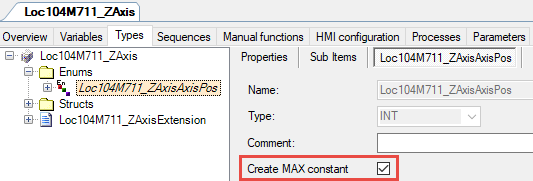

Beginning with Control plus Studio 5.3 you can automatically create constants for the maximum value of an enumeration:

This is a great feature to use the constant as an array limit, for example for the axis teach points in station data and for FOR loops in the PLC.

Still looking for something?

- Top Results